Filters (0)

Agriculture

Public Works

Railway

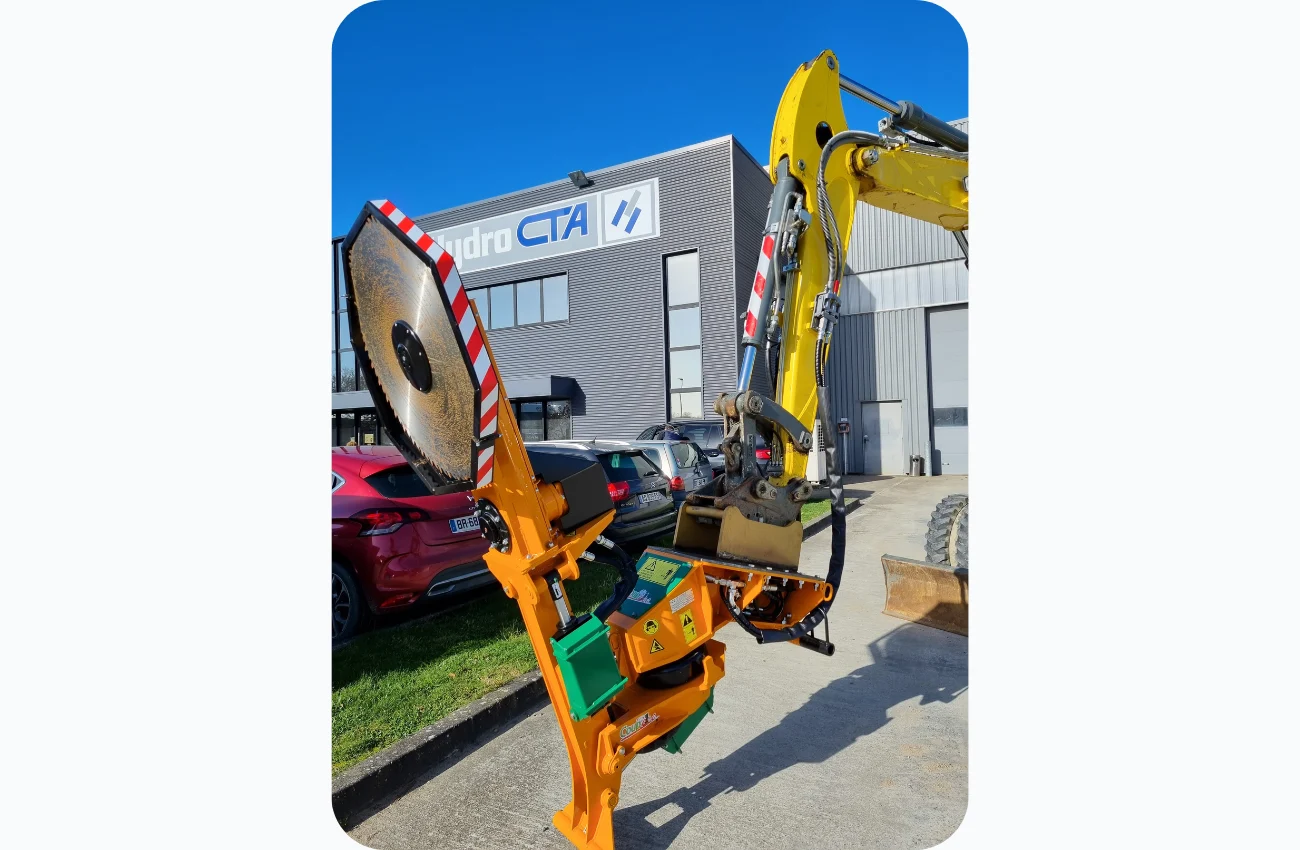

Meteor P360

Discover the Meteor P360, a single-blade cutter designed for demanding pruning jobs. Designed for pruning at great heights, it allows you to work with precision, efficiency and safety, while reducing handling.

Range

Adapted supports

Reinforced single-blade lamina

Cut on 3 sides without moving the carrier

Cutting capacity up to 500 mm

Compact left/right orientation crown

3-movement function selector (tilt / orientation / cut)

Series replenishment valve

Compatible with all brands (interface optional)

Drop-off feet for secure storage

Hydraulic vane motor, integrated safety valve

| Model | Meteor P360 | Meteor P360 |

|---|---|---|

| Pruner | 1700 | 1900 |

| Number of blades/trays | 1 | 1 |

| Diameter (mm) | 700 | 900 |

| Cutting capacity (mm) - Platters | 25 | N/A |

| Cutting capacity (mm) - Saw blades | 240 | 500 |

| Cutting length (m) | 0,7 | 0,9 |

| Hydraulic flow rate and pressure | 45 L/min at 180 bar | 75 L/min at 180 bar |

| Rotation speed (rpm) | 2000 | 1600-1900 |

| Machine weight (without attachment) (kg) | 550 | 580 |

Need answers to your questions ?

The range is intended for hedgerow trimming, pruning, field edge work, topping, or precision cutting. It is particularly suitable for agricultural land or roadside areas, thanks to its robustness and its ability to accommodate different tools depending on the diameter of the branches to be cut.

Yes, with a simple attachment and ease of use facilitated by the carrier's functions.

Yes, a pruning shear can be installed as original equipment.

Variable according to the installed tools; adaptable on demand.

All types of carriers; only the weight and hydraulic flow are decisive.

No, but these models can be seen at the various trade shows we participate in.

15 cm with Ø500 saw 18 cm with Ø600 saw 20 cm with Ø650 saw 25 cm with Ø700 saw 40 cm with Ø900 saw

The single-blade for demanding sites

For what uses and for which professions?

The Meteor P360 was designed by our design office to meet the demands of professionals facing heavy cutting needs at height or on complex vegetated linear areas. It naturally finds its place in the sectors of agriculture, public works, and railways, where managing vegetation near infrastructure is a crucial issue. This hedge trimmer is perfectly suited for intensive pruning work, along roadsides, railway tracks, or on embankments.

Mounted on an excavator starting from 10 tons, it allows for intervention without constantly having to reposition the carrier. Thanks to its cutting capacity of up to 50 cm in diameter, it proves particularly effective for structural cuts, felling large branches, or leveling hedges.

The advantages of the Meteor P360 model

The P360 offers exceptional cutting capacity up to 50 cm in diameter, ideal for heavy-duty interventions and the most resilient plants. Thanks to its monolame structure, it guarantees a clean, precise cut, and especially at the trunk level, which limits tears and promotes natural healing, essential for preserving the health of the trees.

Its reinforced disc (700 or 900 mm) ensures consistent performance even with intensive use. With the Meteor P360, all cutting movements are possible, to the right as well as to the left.

Another advantage is its hydraulic flow rate (85 L/min at 140 bar) calibrated to ensure a smooth and uninterrupted cut, even in dense vegetated environments. The universal mounting easily adapts to different types of excavators, with customized adaptation options according to needs. Finally, the assembly is designed to minimize the maintenance, with easy access to wear parts, proven robustness of the welded chassis, and reliable transmission.

The Coup’Eco Commitment

At Coup’Eco, we design and manufacture all our equipment in France, in our 3000 m² workshop in Pons, Charente-Maritime. That's where our teams bring solid, reliable machines to life, designed to last and truly serve professionals in the field.

Our production site is complete: welding, painting, precision cutting... everything is done on-site to ensure robust and quality products. We know the needs of the field well, and that is what guides our technical choices. Working with Coup’Eco means trusting a French company, close to its users, with machines that are reliable.

Why choose Coup Eco?

Coup’Eco, 30 years of innovation serving your needs

Made in France

All our machines are designed, assembled, and tested in our workshops in Pons, Charente-Maritime.

Quality and robustness

Built from high-quality materials, our machines are engineered to withstand demanding worksites and deliver reliable performance.

Ecological and responsible

Our machines ensure clean cuts, promote healthy regrowth, and help reduce plant diseases.

Market leader in France

A pioneer and specialist in mechanical pruning since 1995, offering a range of solutions tailored to each industry sector.

Need advice?

Our experts are here to help you make the right choice. Take advantage advice tailored to your needs, your business and the way you work.

Request a quote for free !Need spare parts?

To extend the lifespan of your machines or handle unexpected issues, we offer spare parts suitable for all our models.

Submit a request